porous ceramic filter is constantly pursuing the best technology available on the market to produce the best quality aluminum ingots, aluminum round bars or aluminum strips for its customers. Our guarantee will not stop at customers, but will continue to provide customers with quality products! Our Casting Filter can ensure the production of high-quality cast aluminum for the porous ceramic filter.

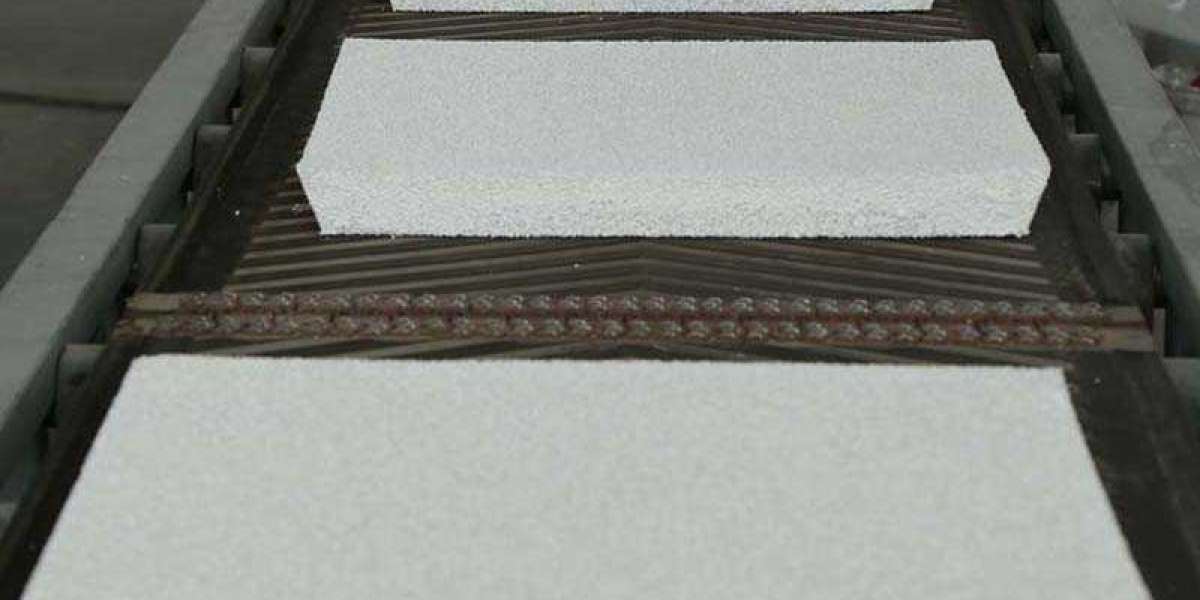

The casting Filter removes the inclusions generated between the refining system and the mold table.

The ability of the ceramic foam filter to capture these inclusions is critical to maintaining a clean ingot during the solidification of the metal.

Therefore, the quality and productivity of downstream operations such as forging, extrusion, and rolling are guaranteed.

Keyword=aluminum ceramic foam filter, ceramic foam filter, ceramic filter plate, porous aluminum plate, silicon carbide ceramic foam filter, alumina ceramic filter, alumina foam filter, the molten metal filter, foundry filter, Cast filter.

What kind of aluminum ceramic foam filter does porous ceramic filter provide?

1. Improve mechanical properties

2. Reduce signs of dye penetration

3. Reduce rework/scrap;

4. Improve processing performance.

Norway Aluminium said that Adtech porous ceramic filter can effectively remove large impurities in molten aluminum and effectively adsorb small impurities. The factory workshop gave the following feedback

1. There is no chipping off, effectively reducing the pollution of molten aluminum.

2. Excellent thermal shock resistance, improving the erosion resistance of the molten metal.

3. Improve surface appearance and performance, purify molten aluminum.

Therefore, Norway Aluminium is recommending this product to other porous ceramic filter plants in Norway.